Raised Ink Business Card Printing

Raised Ink (Thermography) Business Card Printing

Business Cards – Specialty

Our Products

SINGLE SIDED PRINTING – 1 COLOUR

360gsm artboard.

PRESS READY PDF HELP

Having trouble setting up your press ready PDF? Email us print@absolutecolour.com.au with your art file, fonts and links and we maybe able to do it for you at no cost

ORDER NOW – PAY LATER

Need something different?

SINGLE SIDED PRINTING – 2 COLOUR

360gsm artboard

ORDER NOW – PAY LATER

Need something different?

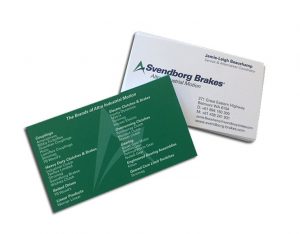

DOUBLE SIDED PRINTING – 1 COLOUR

360gsm artboard

ORDER NOW – PAY LATER

Need something different?

DOUBLE SIDED PRINTING – 2 COLOUR

360gsm artboard

ORDER NOW – PAY LATER

360gsm artboard

Need something different?

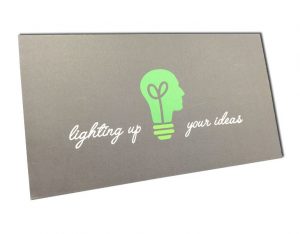

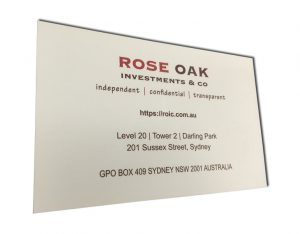

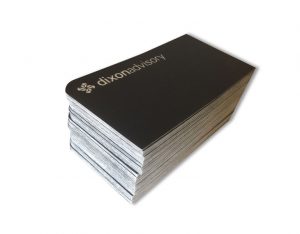

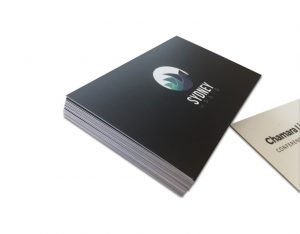

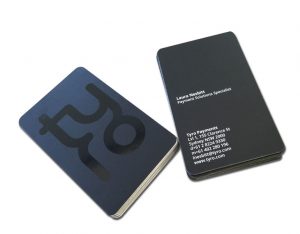

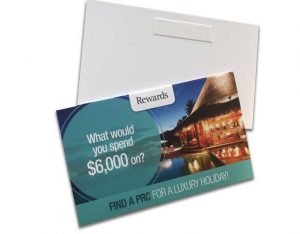

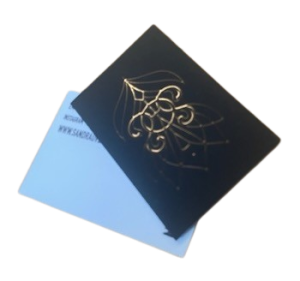

Ideal for Raised Lettering or Logos on Business Cards

Looking for that old school look for your business cards?

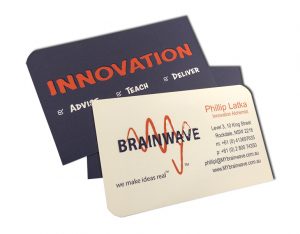

Before CMYK became a big thing, raised ink/thermography was in vogue. It usually involves one colour, maybe two and is well-suited for minimalist business card printing.

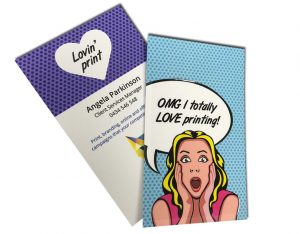

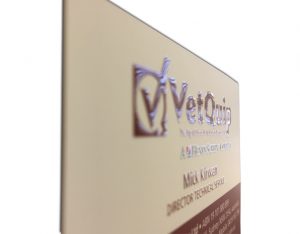

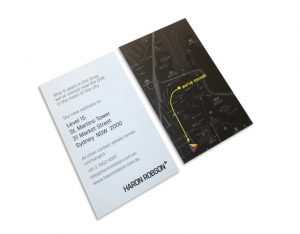

How does it work? Thermography requires the lettering or shape intended to be raised to first be printed. While the ink is still wet, a resin powder is sprinkled onto it. After this, any excess powder is vacuumed off and the print project is heated. As it heats, the resin melts, slightly bubbles and lifts upwards. This traditional method of printing creates a totally unique finish.

Our designers will create your artwork ready for raised printing. Just email your logo or lettering with your design and we will take care of the rest.

Lettering with Raised Ink Business Card Artwork and Printing

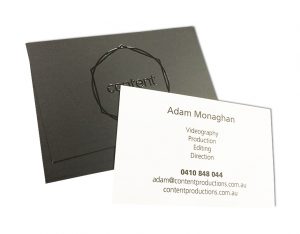

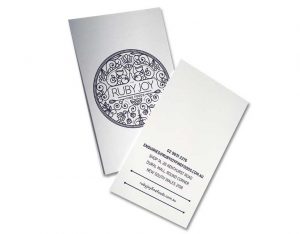

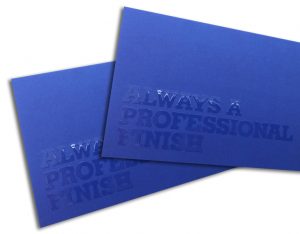

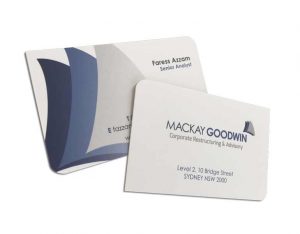

Raised printing was originally designed to simulate embossed engraving at a lower cost.

The process is carried out with a ‘thermo’ unit attached to the end of the printing press where freshly printed inks are dusted with a clear compound.

As the excess powder on the non printed areas is removed by vacuum, the sheet passes under a heater set at 480 – 700 degrees Celsius. This fuses the ink and powder compound together. The sheet is immediately moved into a cooling section where the raising is stopped.

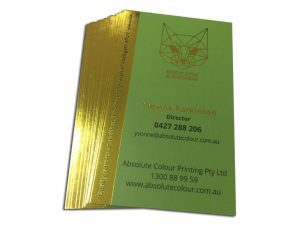

The finished product looks high end and distinctive to the eye and touch.

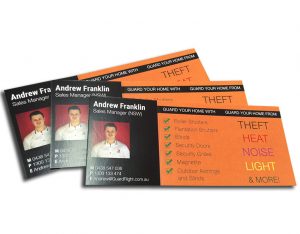

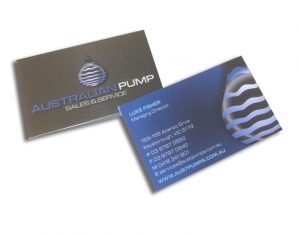

It’s a perfect choice for business cards, swing tags, certificates, menus and invitations.

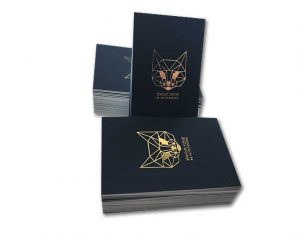

Choose from the many Pantone Ink colour options available.

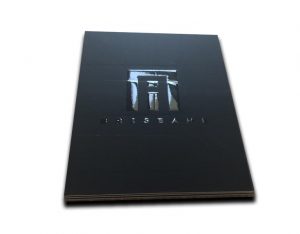

- High impact as printing stands out more

- Able to match virtually any company colour

- Unique texture, look and feel

- Choice of 4 stocks

- Lower cost than Letterpress printing

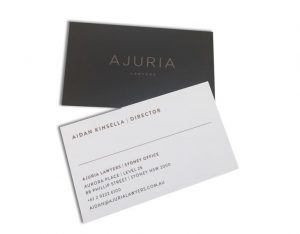

Specifications:

- 54 x 89mm

- 360gsm satin artboard available with matt celloglaze 2 sides

- 350gsm ivory board

- 300gsm Brilliant or Cream Conqueror

- 280gsm Linen Board

- Pantone Colour Matching System or Black Inks used